-

EFFICIENCY

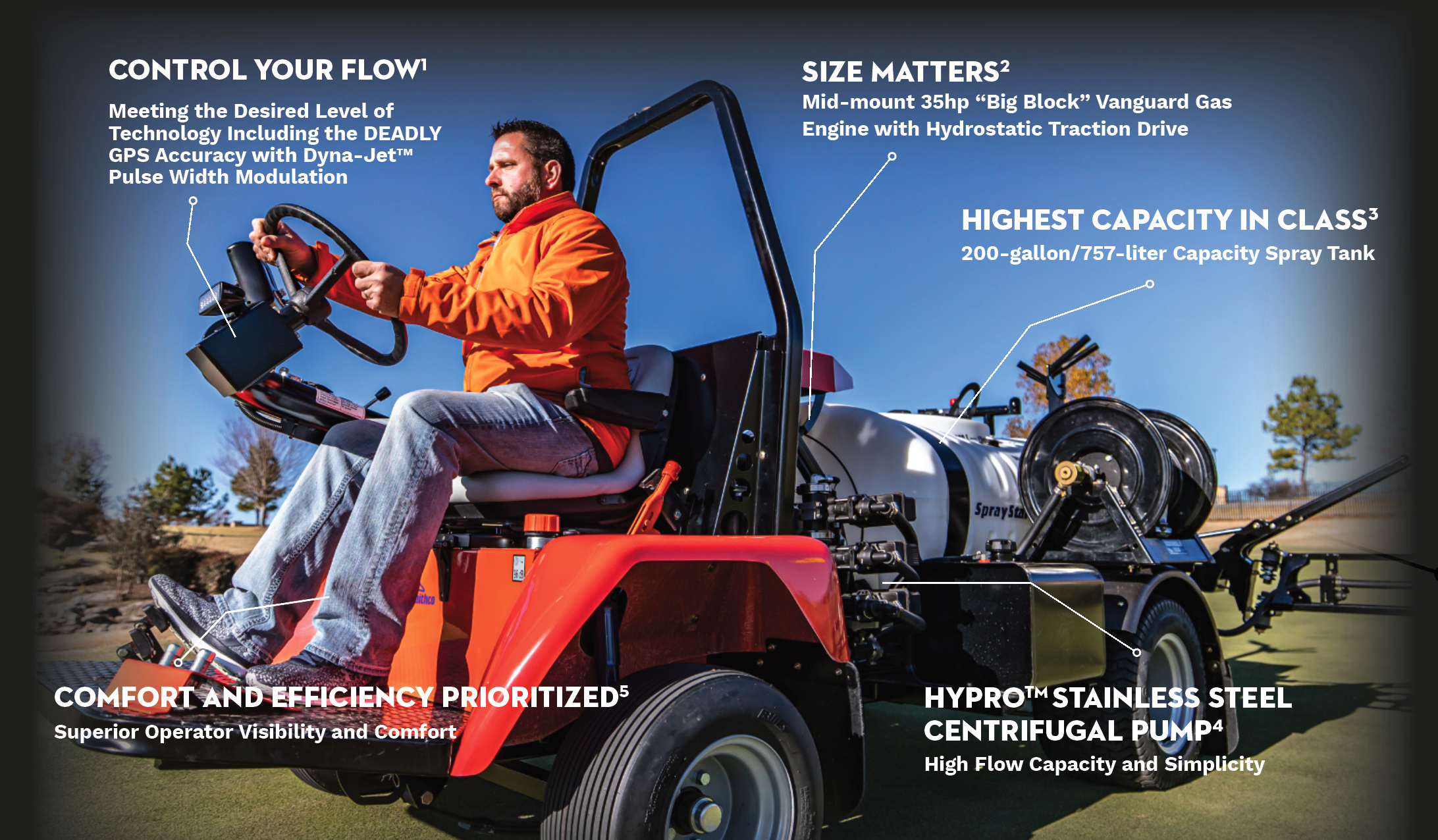

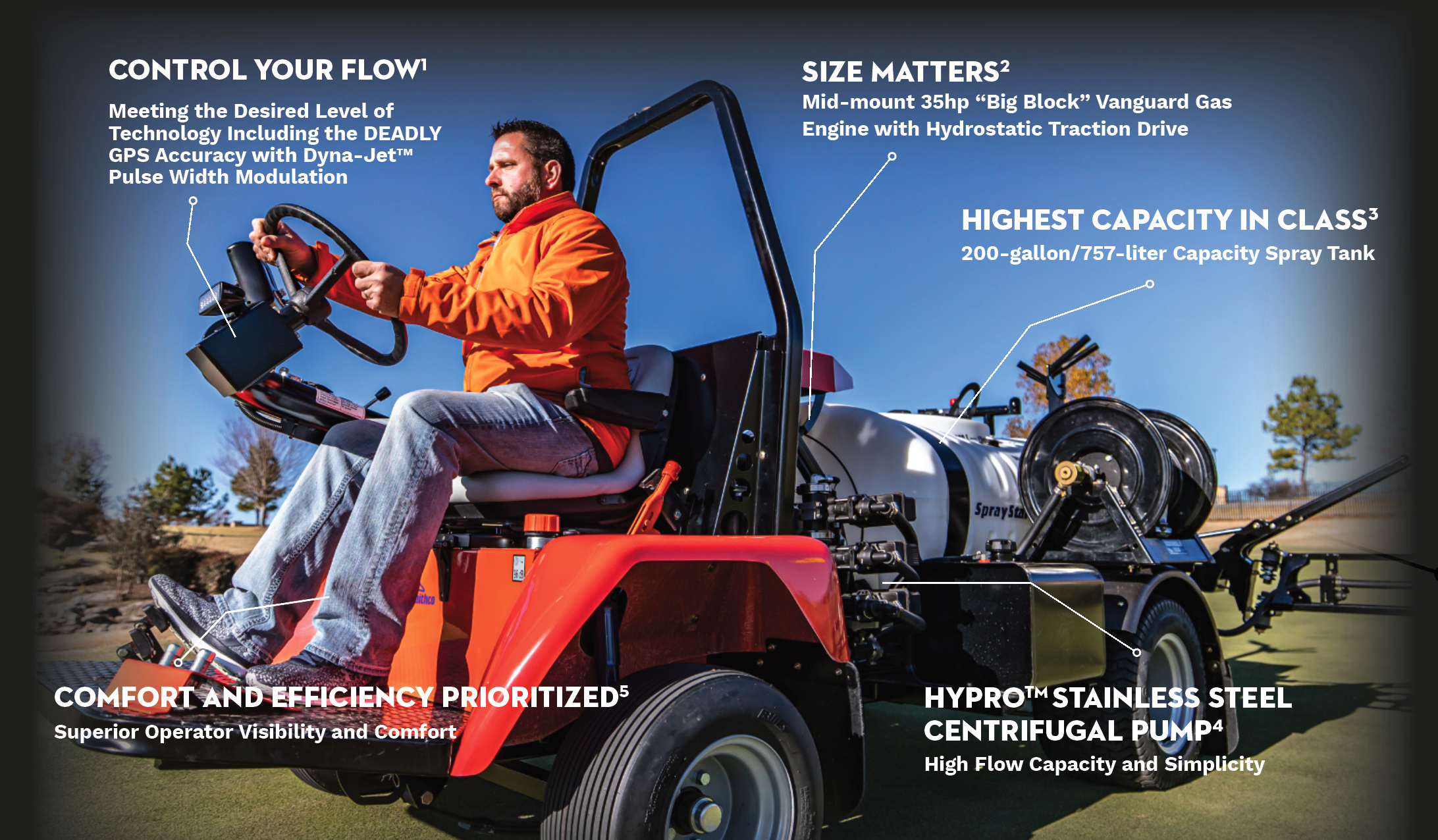

Save time and money with the Spray Star 1200. The most accurate spray technology at your fingertips.

-

PRECISION

GPS-enabled with our state- of-the-art Star Command ensures a precise application every time.

-

DURABILITY

Superior construction and materials combine to ensure industry-leading longevity across our product lines.

-

RELIABILITY

Family-owned since 1967, Smithco products are built to last. Great people make great products.

-

EFFICIENCY

Save time and money with the Spray Star 1200. The most accurate spray technology at your fingertips.

-

PRECISION

GPS-enabled with our state- of-the-art Star Command ensures a precise application every time.

-

DURABILITY

Superior construction and materials combine to ensure industry-leading longevity across our product lines.

-

RELIABILITY

Family-owned since 1967, Smithco products are built to last. Great people make great products.

STAR COMMAND FEATURES

No one matches our 9 years of experience developing the most precise application available for spraying chemicals on turf. With our Partner, TeeJet® Technologies, the Star Command System features all of TeeJet’s® previous benefits available on every Star Command sprayer, as well as these exclusive new features:

corrects flow to keep application rates on target through turns as tight as 20 feet. It lets you avoid straight- line applications on contoured area or rates varying as much as 50% from the inside to the outside of a boom. That doubles the application rate on the inside and cuts the outside rate in half.

to cut off-target applications in half. This spacing also allows for more efficacy because of increased overlap of the spray patterns.

TeeJet’s® new job computers operate up to 100 nozzle sections that can be controlled individually. This eliminates the need for extra cabling and job-stopping failure of mechanical switches.

is also incorporated into the Matrix 908 controller, eliminating extra cabling and separate controller.

significantly reduces Convergence Time, to as little as 90 seconds or less.

Spray Star 1200 Specifications

Star Command 1200 Specifications

IMPERIAL

METRIC

| ENGINE | |

|---|---|

| Type | Vanguard V-twin air cooled |

| Displacement | 54.68 cu.in. |

| Rated Horsepower | 35 hp |

| Air Cleaner | Double Action air intake filtration Engine mounted cyclonic filtration system |

| Cooling | Air Cooled |

| Lubrication | Full Pressurized |

| Oil Filter | Full Flow, Spin on type |

| Electrical System | 24 amp, with 12V 900 CCA battery, fuse protected |

| Fuel Capacity | 10 gallons |

| Traction Drive | |

|---|---|

| Traction System | Hydraulic power to two rear wheel drive |

| Hydraulic System | 5 gallons |

| Hydraulic Cooling | Full flow filter with oil |

| Tires, Brakes and Steering | |

|---|---|

| Tires | Front: 20-10.00×10 Turf Rear: 24-13.00×12 Multi trac |

| Service Brakes | Dynamic braking through hydrostatic transmission |

| Parking Brake | Auto spring pressure release park brake Manual engagement to both rear wheels |

| Steering | Steering Hydraulic Power Steering with orbitrol motor. 15” steering wheel with tilt adjustment |

| Speed | |

|---|---|

| Transport | 0-12 mph |

| Spray Tank | |

|---|---|

| Capacity | 200 gallons |

| Construction | Eliptical polyethylene with UV inhibitors. 16” hinged lid with built in locking device and nylon strainer basket |

| Filtration | Downstream filtration 50 mesh strainer |

| Agitation | Agitator with 4 venturi volume boosters |

| Pump | Rocker switch operated. 10-70 gpm (36-225 lpm). 10-60 psi (0-7.4 bar). Stainless high volume centrifugal with silicon carbide seals. |

| Spray Performance | |

|---|---|

| Application Rates | 20-220 gallons per acre 0.5-5 gallons per 1000 sq.ft. |

| Production Rate | 6.4 acres/hour @ 3.5 mph Up to 75 acres per day |

| Weights and Dimensions | |

|---|---|

| Weight | Dry – 1877 lbs Loaded – 3626 lbs |

| Length | 127” |

| Width | 65” |

| Height | 78” |

| Wheelbase | 68” |